Moisture Sorption of Polyisocyanurate

Introduction

This text refers to the technical bulletin on Moisture Sorption of Polyisocyanurate of the PIMA association.

This Technical Bulletin is a primer on the moisture sorption characteristics of building materials, like polyisocyanurate insulation (polyiso). When applied according to intended use in code-compliant wall and roof assemblies, polyisocyanurate insulation products manufactured in accordance with ASTM C12891 have demonstrated successful moisture durability performance and low moisture absorption while also providing a high level of thermal performance. The response of building materials to moisture is an important factor when considering the appropriate use of common building materials as wide ranging as wood, steel, concrete, various types of insulation, gypsum, and other natural or synthetic building products. The appropriate use of a building material depends on a variety of factors including its intended function, the actual moisture exposure in end use, and the consequence of a given level of moisture exposure. Ultimately, moisture presents a building risk that must be properly managed through intelligent design, building code compliance, and effective building maintenance.

Let’s explore why…

What is Moisture Sorption?

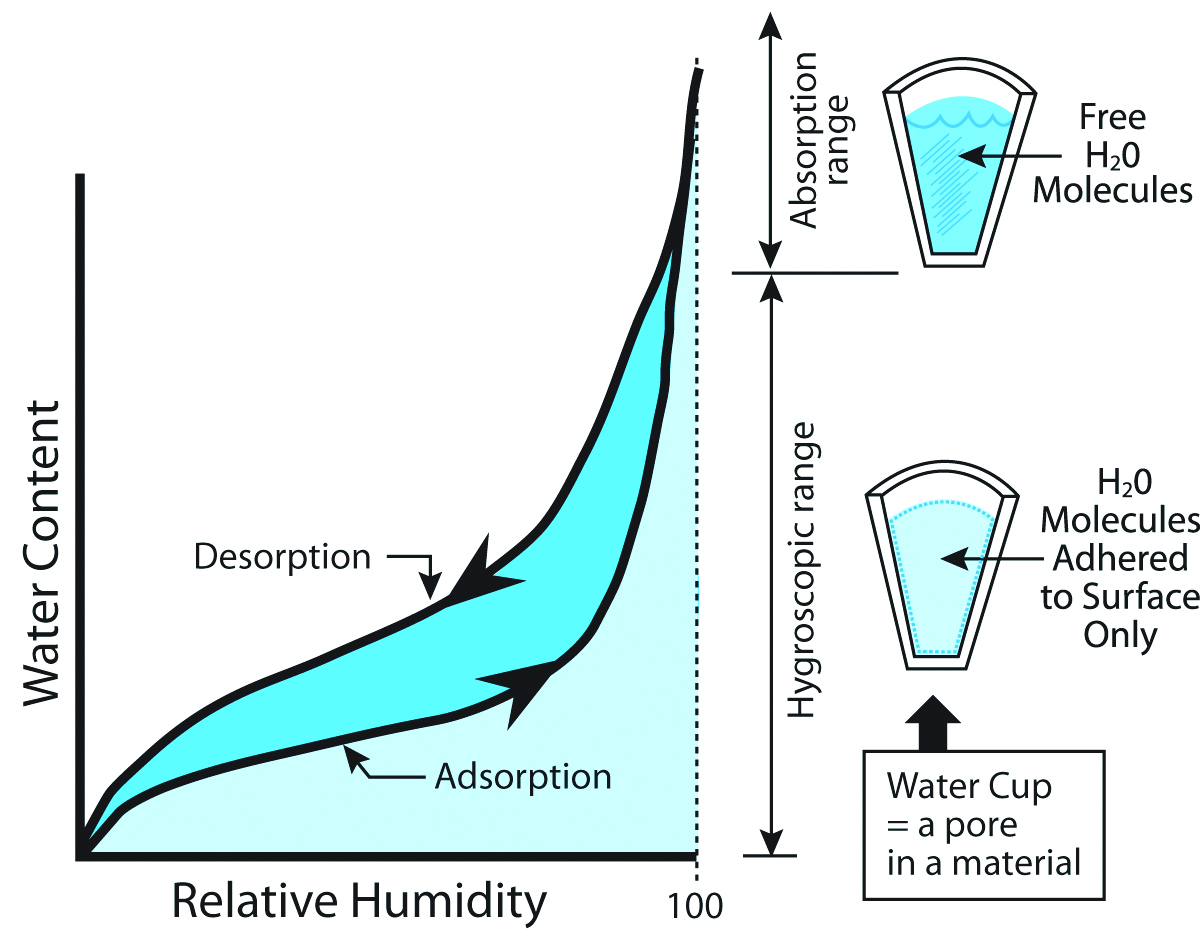

Moisture sorption is actually a fairly complex process. But for practical purposes, there are essentially two ways that materials take-up and release moisture (see Figure 1). Perhaps the most familiar process is absorption. In this process, bulk (liquid) water is taken directly into the pores of the material and is similarly released as liquid water. For example, a sponge or paper towel absorbs liquid water which can be easily expelled again as liquid water by squeezing or drainage by gravity. However, the water that still remains is more strongly held in the material by a process that is a bit more complex and difficult to observe. This process is “hygroscopic” in that it deals with a process by which water molecules are attracted to and adhered to the internal pore surfaces of a material. Water intake in this manner is known as adsorption and its removal by this process as desorption. This hygroscopic form of moisture sorption can change the moisture content of a material simply based on changes in the relative humidity (water vapor content) of the surrounding air without any direct contact with liquid moisture.

The following relevant definitions are found in ASTM C2092 :

3.3.4 sorption – a general term in physical chemistry used to describe the combined processes of:

absorption – refers to the taking up of matter in bulk by other matter, for example, the penetration of substances into the bulk of another solid or liquid

adsorption – refers to surface retention or adhesion of an extremely thin layer of molecules to the surfaces of solids or liquids with which they are in contact.

Figure 1. Illustration of two ways moisture interacts with materials to affect moisture content.

Did you know?…Apples are not Oranges.

Moisture content is measured in two different ways. For insulation product standards, moisture content is commonly reported on the basis of the volume of the water measured within a standard size (volume) specimen. This is known as a volumetric water content. In other cases and for other materials, water content may be reported as the weight of water divided by the oven-dry weight of a standard size specimen. This is known as a dry weight (mass) based water content. While both measure the same thing, the magnitude of reported moisture content is very different and can be confusing. Be sure that moisture content measurements are reported on a common basis to avoid making an “apples-to-oranges” comparison. Moisture contents (MC) can be converted from one basis to another as follows: MC (% volume basis) = MC (%volume weight basis) x (Density of Material / Density of Water or 62.4 lbs/ft3)

Comparative Performance of Various Building Materials

Building materials exhibit a wide range of moisture sorption characteristics. These characteristics are measured in two different ranges corresponding with the two types of moisture intake discussed in the previous section.

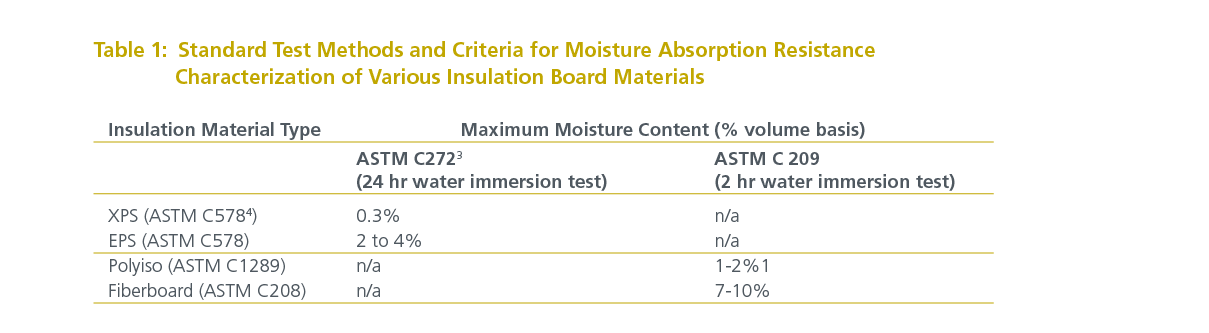

The first form of moisture sorption is absorption of water in the liquid form. Various standard test methods are available to provide an “index” of the moisture absorption characteristics of a material. The primary purpose of such test methods is to evaluate material properties by measurements taken under standardized and repeatable laboratory conditions. These measurements are then used to ensure that minimum material properties are achieved so that acceptable performance is maintained for a specific product’s intended use.

Table 1 below provides a few examples of standard moisture absorption test methods and maximum moisture content criteria for the standardization and qualification of some common insulation materials. Where identical test methods are not used (e.g., ASTM C2723 vs. ASTM C 209), comparison of results or criteria is inappropriate. Even when identical test methods are used, extrapolation of results to draw conclusions on actual end use performance for the purpose of comparison is equally inappropriate from a practical standpoint. These standardized or index test methods are not intended to replicate actual end use conditions. In fact, the primary exposure of many building materials to moisture is through the adsorption/desorption process, not the absorption process resulting from liquid water exposure (which usually has much more significant consequences than any potential singular impact to insulation performance). Most building materials are not intended for exposure to liquid moisture or even uncontrolled levels of moisture vapor. It is for this reason that wall and roof coverings, water-resistive barriers, and vapor retarders are required for code compliance and must be properly designed, located, and detailed in accordance with the applicable building code.

Table Note: 1.Values as low as 0.3% are achievable with foil-faced polyiso, even when evaluated using test methods like ASTM D2824 which calls for 96 hours of water immersion.

4 ASTM C 578-08, Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation, ASTM International, West Conshohocken, PA.

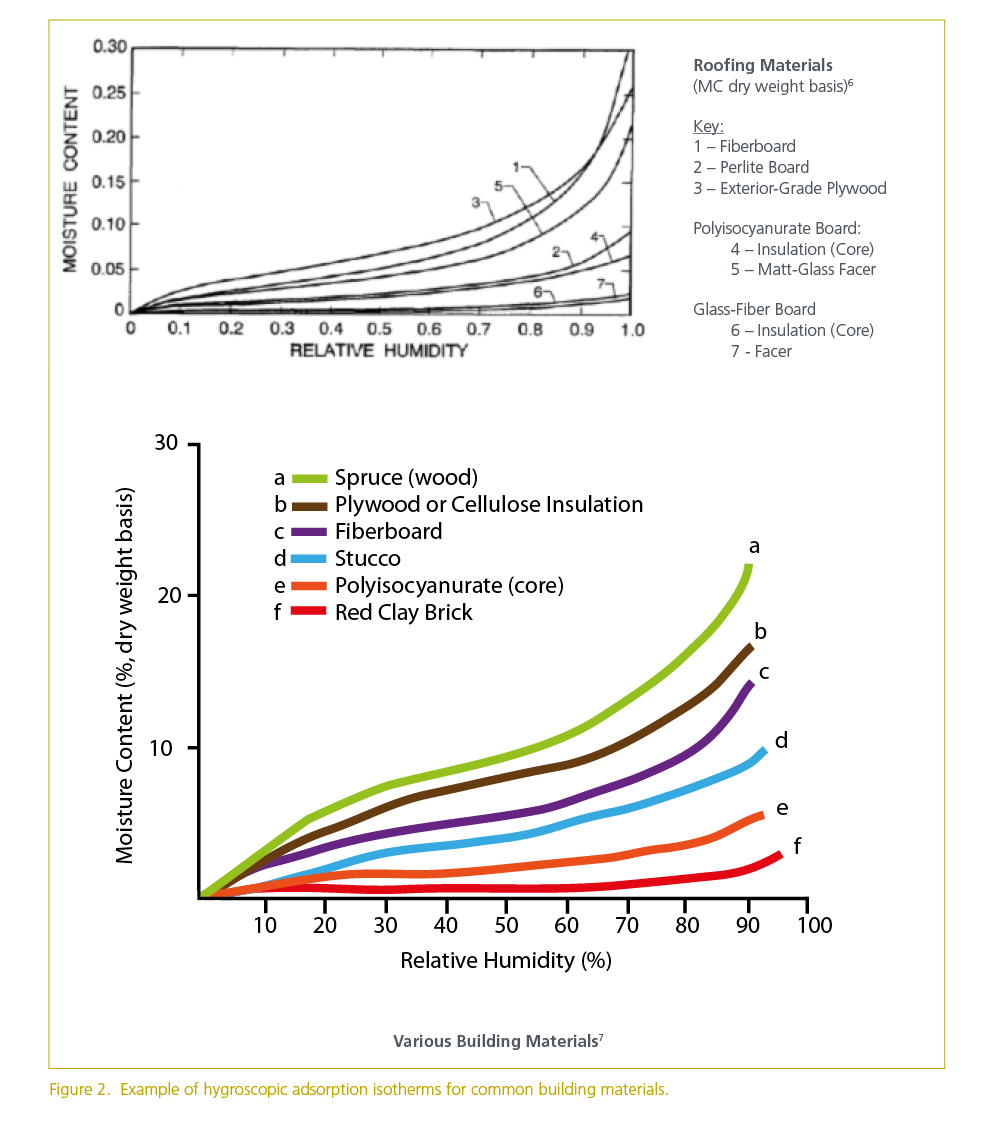

The second process of a material’s interaction with moisture is “hygroscopic” which, as mentioned, deals with the fixation of water molecules on the internal pore surfaces of materials. Adsorption is the intake of water in the hygroscopic range and desorption is the release of moisture in the hygroscopic range. This process is shown in hygroscopic adsorption isotherms of Figure 2 for a variety of building materials. Hygroscopic sorption isotherms are measured in accordance with ASTM C14984. A hygroscopic moisture isotherm is a plotted curve representing the equilibrium moisture content of a material (vertical axis of chart) at a given relative humidity of the surrounding air (horizontal axis of chart). These isotherms differ for moisture in-take (adsorption) and release (desorption) for any given material (see Figure 1). The sorption isotherms explain a material’s

response (wetting or drying) to changes in relative humidity of the surrounding environment.

Understanding the data…

In Chart (1) of Figure 2 above, it is observed that polyiso insulation (material #4) is a moderately sorptive or hydrophilic material in comparison to the other common building materials. It is also interesting that at the 100% relative humidity exposure level, the moisture content (dry weight basis) maximized at 0.06 (or 6%). Using the conversion to a volumetric moisture content basis, the value is 0.06 x (2.1/62.4) = 0.002 or 0.2% moisture content. This is a relatively small amount of moisture intake under severe relative humidity conditions. It is about 1/10th the amount of moisture intake permissible under standardized water immersion testing addressed next. According to the scientific literature*, this amount of moisture intake under sustained severe humidity conditions has at most a ~10% impact on thermal performance.

Source*: Tobiasson, W., Greatorex, A., and Van Pelt, D. (1991), “New Wetting Curves for Common Roof Insulations,” 1991 International Symposium on Roofing Technology (refer to Figure 9, p388 of proceedings)

Relevance to Roof and Wall System Performance

It is clear from the data presented in the previous section that different materials, including insulation products, have a wide range of moisture sorption characteristics. Even so, it is equally clear that acceptable performance can tolerate a fairly broad range of material moisture response characteristics when the materials are used in a code-compliant manner. Materials intended for or capable of long term performance under direct exposure to liquid moisture are those that are best suited to applications outside of a building’s weather-resistive envelope, such as exterior below grade foundation insulation or protective membrane roof insulation where insulation is placed above the roof membrane and, therefore, is subject to frequent wetting. Polyiso insulation and many other materials are not intended for this type of wet service end-use condition. Such materials must be used within a building’s weather-resistive envelope which means to the inside of the water resistive barrier on walls and underneath the roofing material(s), including underlayment if required. Consequently, some polyiso insulation board products come with an appropriate water-resistive facer to provide the necessary insulation and water-resistive barrier functions to exterior walls. In general, it is desirable to design and maintain buildings such that even moderately moisture

sensitive materials remain reasonably dry. For this reason, untreated wood and uncoated steel structural materials, most insulation materials, and many other types of building materials mustbe protected from excessive liquid moisture exposure by use of code-compliant and functionally maintained roofing system and exterior wall coverings (including a water-resistive barrier) with flashing of wall and roof penetrations such as windows, doors and vents. In addition, moisture vapor must be controlled by code-compliant application of ventilation and/or vapor retarders in accordance with local climatic conditions as well as any special interior moisture loads. Whether due to a lack of code compliance or inadequate maintenance, a wet building does not just affect non-structural or serviceability concerns, such as indoor air-quality or insulation performance. It can also cause structural materials to degrade resulting in safety problems and eventual collapse if not detected. In short, a relatively dry building is a healthy and durable building and most building materials are meant to perform in reasonably dry, code-compliant and properly maintained buildings.

Summary and Conclusions

Moisture sorption involves two processes: absorption and adsorption. Both processes can cause materials to change moisture content depending on end-use conditions. In comparison to many other common building components and materials, polyisocyanurate insulation material is only moderately sensitive to moisture. When manufactured in accordance with ASTM C1289 and used in code-compliant wall and roof assemblies that are functionally maintained, polyisocyanurate board insulation products have demonstrated successful moisture durability performance and exceptionally high thermal performance. It is meant for use in building walls and roofs together with code-compliant roofing and all covering systems. Finally, with use of appropriate water resistive acers and installation details, polyisocyanurate board insulation products can effectively serve a dual role as the continuous insulation layer and the water resistive barrier in code compliant exterior wall assemblies.

Best Practice Recommendations for Polyisocyanurate Board Insulation

“The following recognized properties of polyisocyanurate foam board roof insulation make it an effective insulation material:

- Bitumen and adhesive compatibility

- Component compatibility

- Impact resistance

- Durability

- Moisture resistance

- Thermal resistance

- Attachment capability”

a) Roofing and Waterproofing Manual, 5th Edition (2006 Update), National Roofing Contractors Association (refer to Section 2.5.1)

b) Proper storage of materials, such as polyisocyanurate insulation, and protection from weather and ground moisture when stored outside is recommended. This concern is common to many common materials such as wood sheathing, lumber, gypsum sheathing, and others. For more information refer to PIMA TECHNICAL BULLETIN #109tion, visit www.polyiso.org

REFERENCES

1 ASTM C1289-07, Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board, ASTM International, West Conshohocken, PA.

2 ASTM C209-07a, Standard Test Methods for Cellulosic Fiber Insulating Board, ASTM International, West Conshohocken, PA.

3 ASTM C272, Standard Test Method for Water Absorption of Core Materials for Structural Sandwich Constructions, ASTM International, West Conshohocken, PA.

4 ASTM C 1498-04a, Standard Test Method for Hygroscopic Sorption Isotherms of Building Materials, ASTM International, West Conshohocken, PA.