Fire Resistance Properties of Polyiso

Introduction

This text refers to the technical bulletin on the fire resistance properties of Polyiso of the PIMA association.

Building codes exist to provide a means to safeguard life and protect the private and public welfare through the regulation of the design, construction practices, construction material quality, location, occupancy and maintenance of buildings and structures. Protection from the risks associated with fires is prevalent throughout the codes, and the fire resistance properties of building materials are especially important.

Polyisocyanurate foam plastic insulation, or polyiso for short, meets the most stringent building code requirements for use in buildings of any construction type and is one of the most regulated building products used in the construction of building envelopes. For example, Section 2603 of the International Building Code (IBC) and Section R314 of the International Residential Code (IRC) prescribe general fire test requirements for foam plastic insulation, in addition to specific fire tests, many of them full-scale building assemblies, for specific applications.

However, not all foam plastic insulating sheathing materials — or other commonly used combustible sheathing materials, such as oriented strand board (OSB) – have equal fire performance properties and capabilities. As a result of continuous improvement in the product and years of rigorous testing, the performance of polyiso has been validated in numerous building product tests and in historical practice. While polyiso has many benefits, its fire performance is one more reason why polyiso is a preferred building envelope insulating material.

This technical bulletin provides a synopsis of minimum fire resistance properties required for foam plastic insulation materials and compares data on polyiso with other recognized combustible materials commonly used for building construction, such as polystyrene insulation (i.e., XPS and EPS foams) and OSB. The specific material properties related to fire performance include flame spread and smoke development ratings. In addition, the performance of polyiso with respect to the thermal barrier and ignition barrier requirements of the code are presented. Together, these properties demonstrate the superior performance of polyiso.

Building Construction and Codes

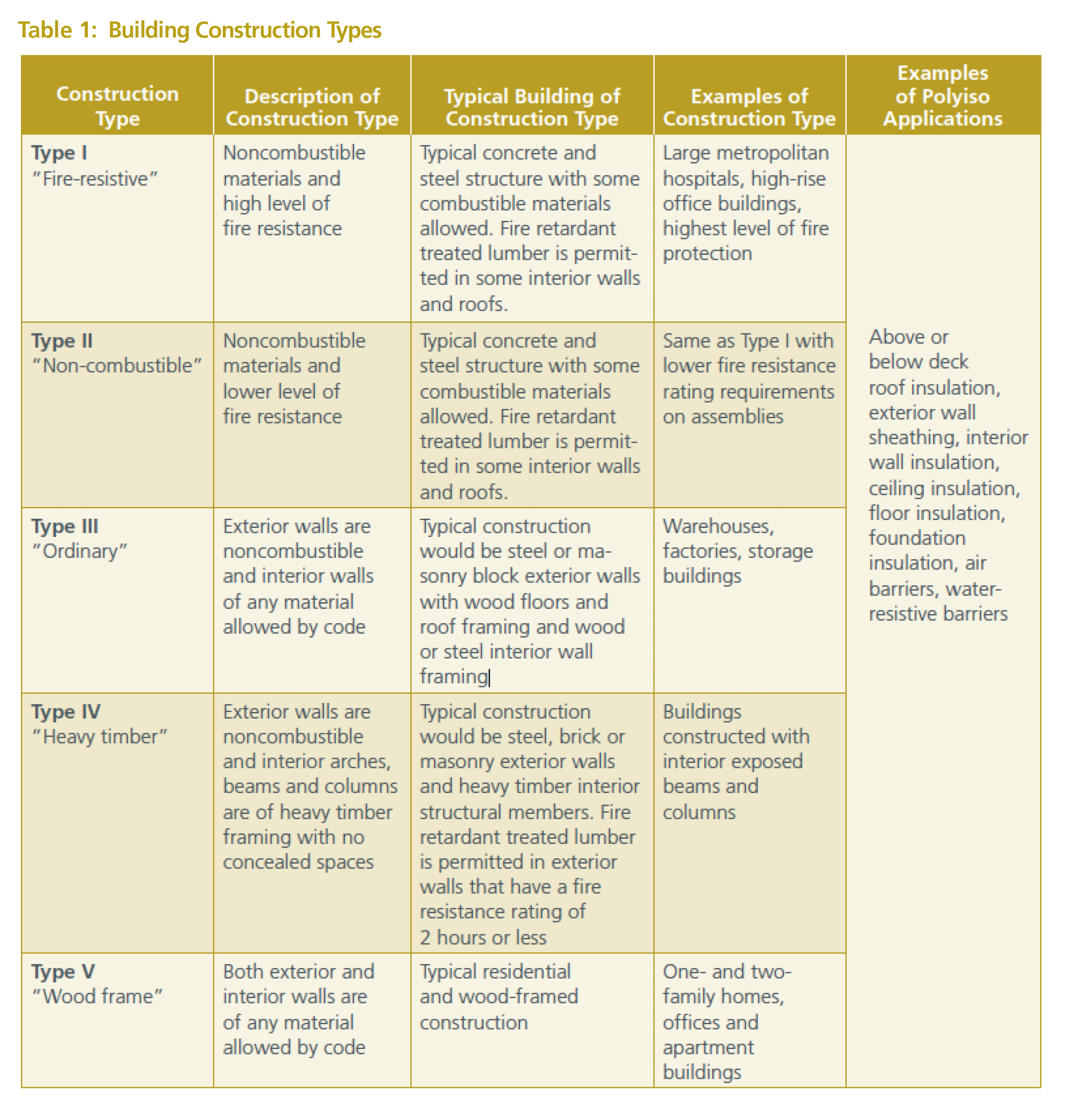

The IBC, IRC and the local codes based upon them establish baselines for building material performance. Requirements are subdivided by the type of construction, as shown in Table 1.

The type of construction used is determined by a number of factors. Building codes contain many limits on the type of construction allowed for a given project, based on the building’s height and area. Further, these height and area limitations can differ depending on the active or passive fire protection strategies employed. The construction types can be thought of as varying levels of fire resistance. The requirements for these levels of fire resistance dictate what materials can be used in their construction. Polyiso, because of its excellent fire performance characteristics, may be used in all building types.

Material Property Data for Fire Resistance

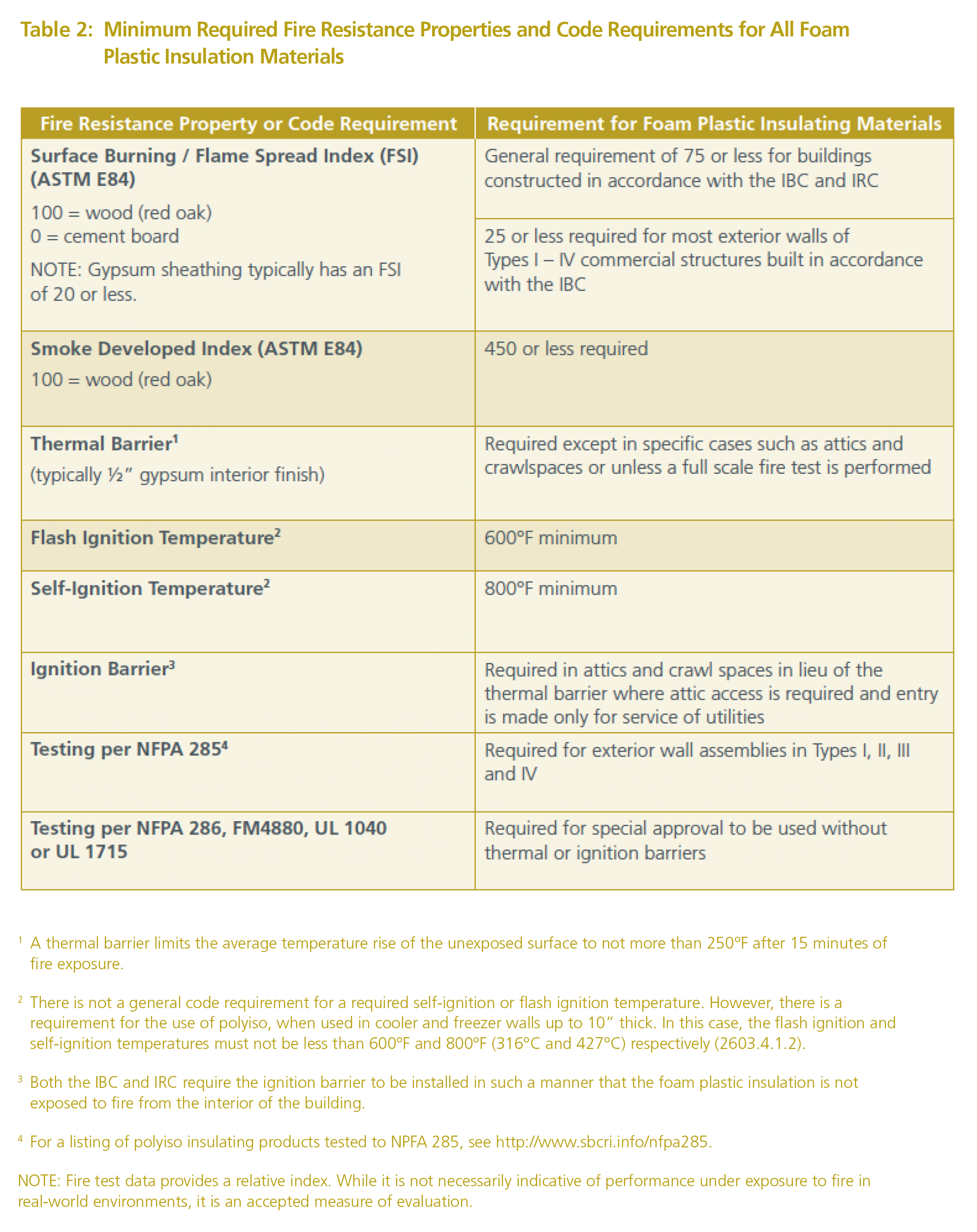

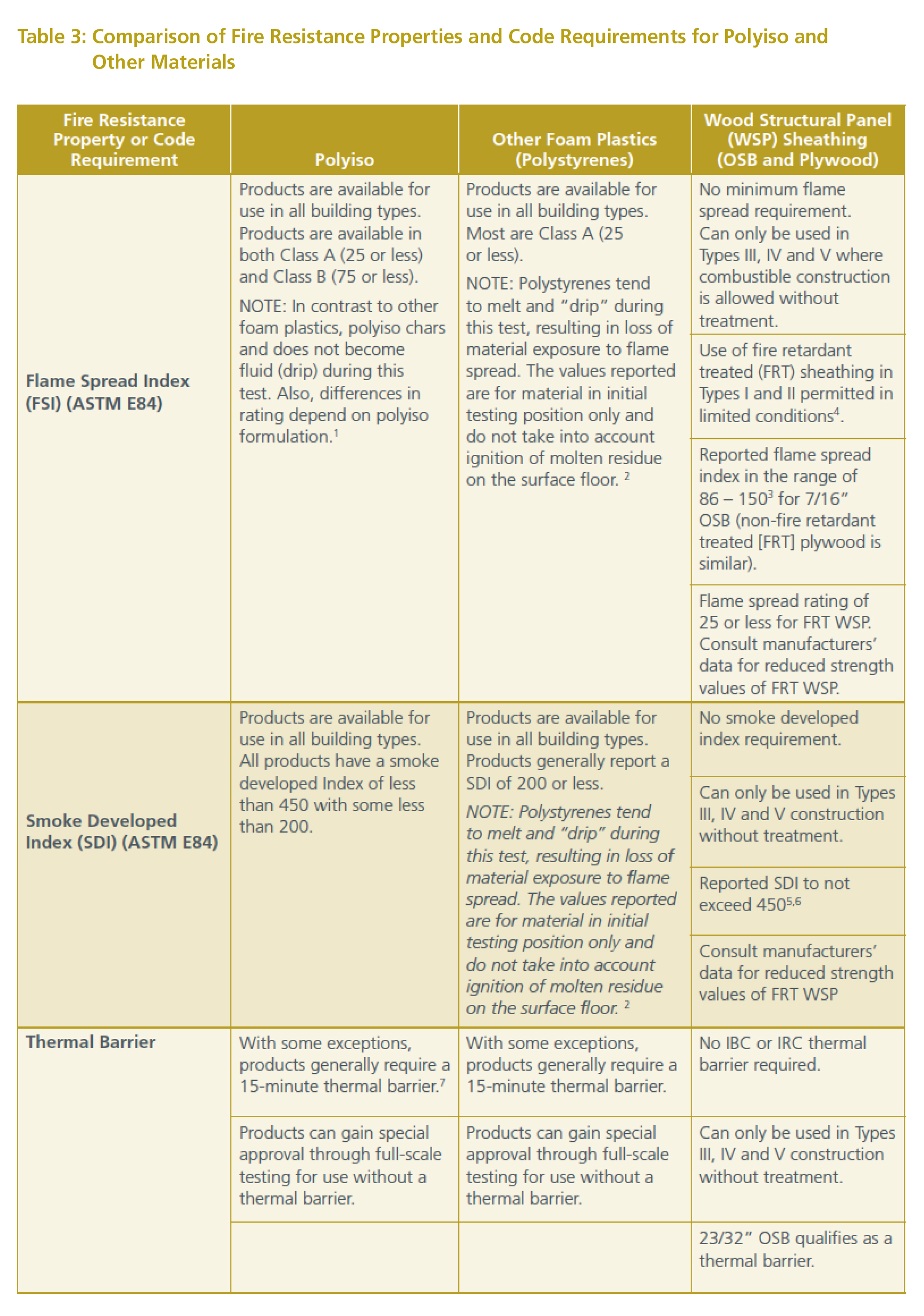

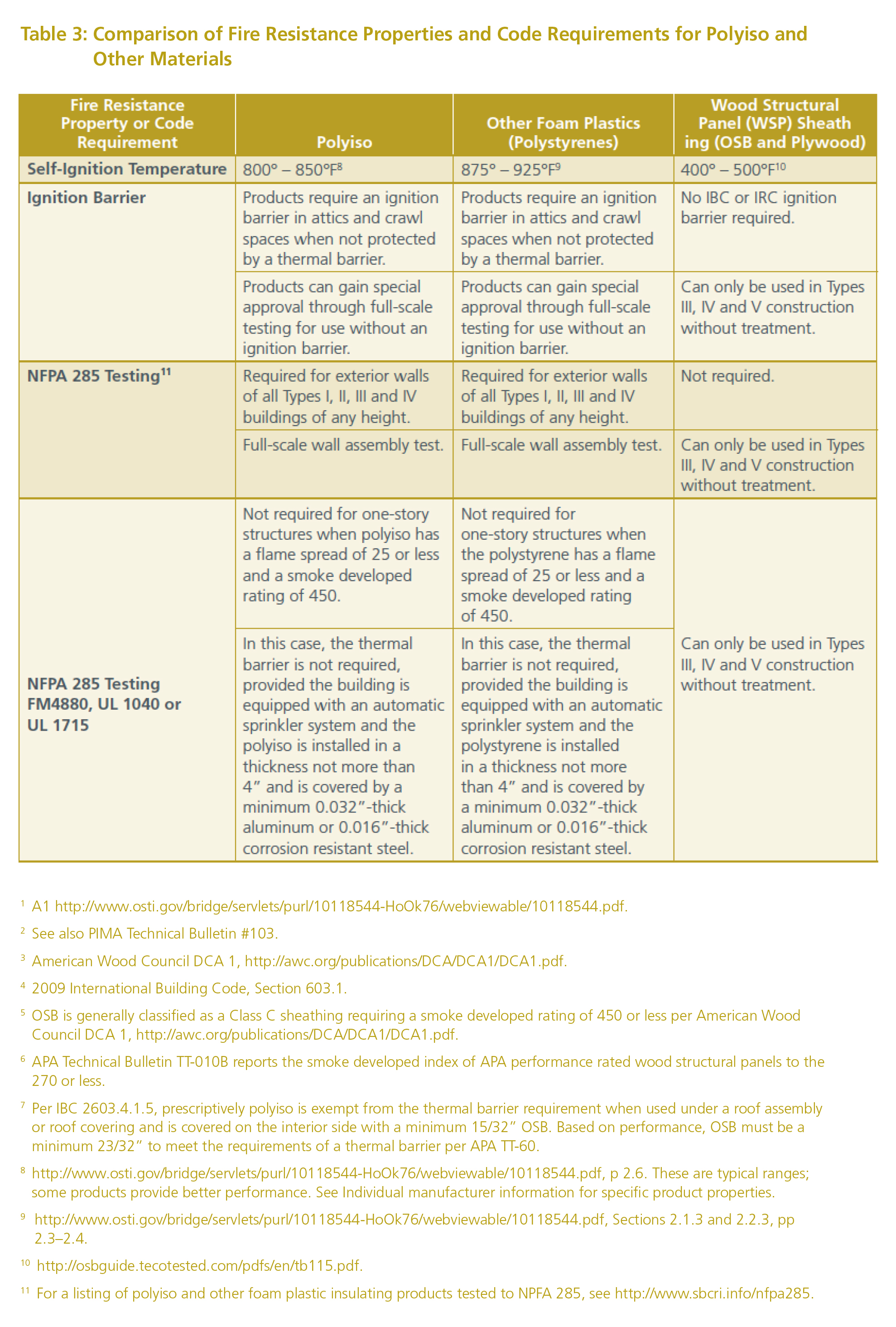

Table 2 presents a summary of minimum material fire performance properties for foam plastic insulating materials based on the building code provisions cited above and other available data. Table 3 compares the actual performance of these same properties for polyiso to other foam plastic insulating materials, such as polystyrene (i.e., XPS or EPS foams) and OSB.

IBC Chapter 26 delineates the requirements of several tests for foam sheathing. These include: §2603.4 Thermal barrier, referencing ASTM E119/UL 263 and FM 4880/UL 1040/NFPA 286/UL 1715; §2603.5.3 Potential heat, referencing NFPA 259; §2603.5.7 Ignition, referencing NFPA 268; and §2603.9 Special approval, referencing NFPA 286/FM 4880/UL 1040/UL 1715. Many polyiso products on the market have passed this comprehensive testing. It is important to note that other common combustible materials, such as OSB, are not required to satisfy similar tests and thus provide unknown fire performance characteristics. Also, wood sheathing products can only be used in combustible construction types if they are fire retardant treated, and that has additional costs and structural performance issues.

Contact your polyiso manufacturer for specific product and assembly test results.

Conclusions

Based on the data presented in this technical bulletin, the following conclusions are substantiated:

- Wood sheathing begins to burn at 400° – 500°F, while polyiso does not burn until temperatures greater than 800°.

- Polyiso offers superior surface burning and flame spread fire-resistance properties in comparison to minimum building code requirements and other common combustible insulating and structural materials used for building envelope construction. Its flame spread characteristics are similar to gypsum wallboard.

- Polyiso has a flame spread index much lower than OSB, yet OSB has no flame spread requirements. All foam plastic products are required to meet a flame spread index of 75 or less. The requirement is more stringent for foam plastic products used in exterior walls of Types I – IV where they must meet a flame spread index of 25 or less.

- Polyiso will not melt or drip when exposed to fire. This is not the case for polystyrene (XPS and EPS), which produces molten material that would also be subject to adding molten fuel to the fire.

- Polyiso, like many foam plastic materials, is generally required to have a thermal barrier, but it has the capability to be used without a thermal barrier when it meets specific testing criteria. Consult a specific polyiso manufacturer for code approval data allowing a product’s use without a thermal barrier.

Wood structural panels, like many wood based sheathing materials, are generally not required to be tested to prove they are a thermal barrier, regardless of fire characteristics. - Many exterior wall assemblies with polyiso insulation pass the stringent NFPA 285 test and can therefore be used in buildings of any type and any height. Wood structural panels have generally not been tested to NFPA 285 and can only be used in Types III, IV and V construction without treatment. If treated, consult manufacturers’ data for reduced strength values of FRT WSP.