Polyiso Insulation in Masonry Cavity Walls

Polyiso Insulation: The Clear Winner

This text refers to the technical bulletin on Polyiso insulation in masonry cavity walls of the PIMA association.

When it comes to selecting the best overall insulation product for cavity walls, polyiso is the product of choice. No other foam insulation has the perfect combination of features so important for long term performance:

- Highest R-value per inch of thickness

- Moisture resistant, water repellent panel sheathings

- Resistant to solvents used in construction adhesives

- Excellent dimensional stability

- Superior performance in fire tests

- Service temperature range from -100F to +250F

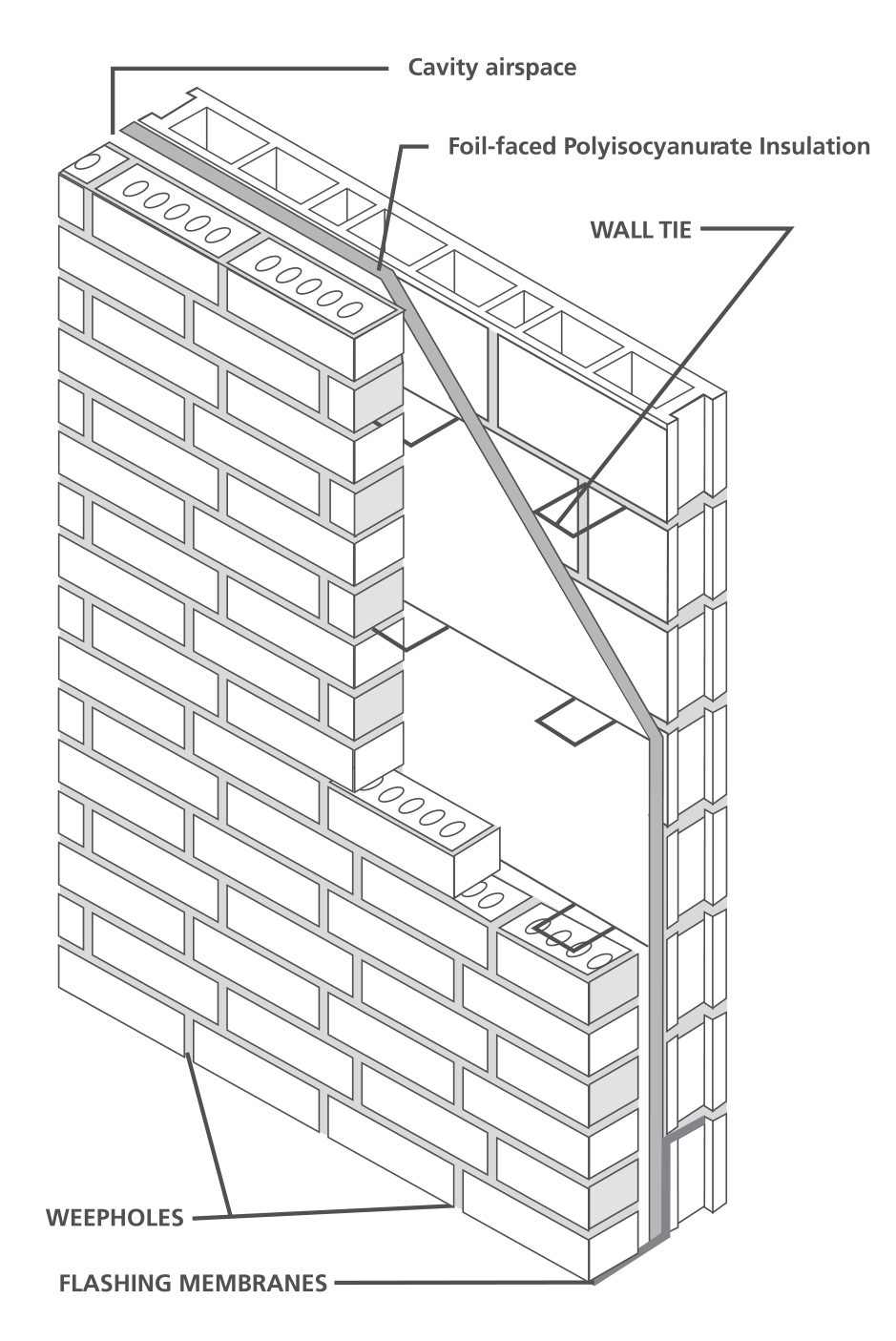

The Cavity Wall

A cavity wall consists of two wythes of masonry, separated by a cavity of varying dimensions. The wythes are generally tied together with corrosion resistant wall ties and are separated by an air space and a layer of insulation board on the exterior of the inner wythe. The wythes may consist of solid brick, hollow brick, structural clay tile, solid concrete, or hollow concrete units (block). Cavity walls provide good rain and weather protection, excellent thermal properties, as well as good sound and fire performance. These basic elements combined with good structural design, PIMA Technical Bulletin #401 appropriate details, quality materials, and good workmanship will result in high performance cavity walls.

The proper cavity wall design consists of insulation installed on the exterior of the inner wythe and an air space adjacent to the cavity face of the outer wythe. This system takes into account possible moisture penetration which can come through the outer wythe during rain events. The small amount of moisture that does penetrate seeps primarily through microscopic cracks between the masonry and mortar bond and down the cavity face of the outer wythe. Organizations that provide cavity wall design details recommend an unobstructed air space. This air space allows the moisture to seep to the lowest level where wall flashings direct the moisture back to the building’s exterior via weep holes. As stated by the Masonry Advisory Council:

“For this reason, an airspace is designed between the veneer and backup to allow moisture to drain down the cavity and exit at flashing and weep holes. A clean airspace provides a space for water to drain down where it can be directed to the exterior at flashing locations. The purpose of a cavity wall is to manage water by removing it to the outside, not collect it in the cavity space.”1

When rigid insulation is placed inside the cavity, a 1” air space must be maintained. Since the required thickness of insulation affects the cost of construction, this requirement makes the choice of the proper insulation critical. Application of high R-value foil-faced polyiso insulation, at thinner profiles than other rigid insulations, allows the architect, designer, specifier, and contractor to provide the best insulation value while maintaining the correct air space design requirement and the most cost effective wall design.

R-value Performance

Foil-faced polyiso has the highest R-value per inch, therefore the design U-value of the cavity wall system can be achieved with a minimum thickness of insulation. This in turn allows the overall footprint of the building to decrease and reduces the cost of construction. Additionally, the thinner insulation helps the cavity wall to function at a higher level as it is able to more efficiently remove water to the outside. The foil-facer is a low permeability material which enhances long term thermal performance.

Moisture Resistant Water Repellent Panels

Foil-faced polyiso insulation is water repellent due to the low impermeability of the facers and the closed cell nature of the foam core. These properties provide long term moisture resistance.

Although a cavity wall is not designed as a wet environment, a cavity wall performs by taking the small amount of water penetrating the outer wythe, draining it down the cavity face of the outer wythe to a flashing which directs the water back to the exterior. With its inherent excellent moisture resistance, polyiso is the perfect choice for this environment.

Excellent Dimensional Stability

Temperature cycling and humidity encountered in cavity wall applications does not affect foilfaced polyiso insulation properties such as dimensional stability and thermal performance.

Thermoset Material

Polyiso insulation is a thermoset material and withstands sustained elevated temperatures compared to thermoplastic insulation, which can begin to soften at 165 F.

Compatible with Solvent Based Construction Materials

Many construction materials such as adhesives, water repellent and preservative coatings, and bituminous damp proofing and waterproofing materials are used in cavity wall designs. These materials, which often contain petroleum-based solvents, do not affect polyiso insulation. However, they can attack thermoplastic insulations, severely compromising their physical and thermal properties.

Easy to Install

- Polyiso is lightweight and easy to handle

- Polyiso is easy to cut and shape and can be easily detailed at the job site for proper installation

- Polyiso is available in 16” or 24” widths depending on the wall tie spacing

- The polyiso insulation is installed between the wall ties to the exterior of the inner wythe with a construction adhesive, insulation grips which snap onto the wall ties, or a combination of both.

Specify Polyiso for Cavity Wall Applications

Foil-faced polyiso — ASTM C 1289-03 Type I Class 1 — is the product of choice for masonry cavity wall construction.

Polyiso Is the Best Insulation For Cavity Wall Applications

- Foil-faced polyiso products have higher long term R-values compared to other rigid board products

- Foil-faced polyiso insulations are moisture resistant water repellent foam panels that can be specified with confidence

- Polyiso is the environmental “green” choice

- Polyiso is CFC– and HCFC–free, providing the architect, specifier, designer and contractor with an insulation that has zero ozone depletion potential (ODP) and negligible global warming potential (GWP).

REFERENCES

1Cavity Wall Design Guide, Masonry Advisory Council, www.maconline.org