Synthetic Roofing Underlayments

Waterproofing roofs, whether residential or commercial, has always been an important topic for homeowners. Roofs are exposed to natural elements, such as rain, snow and wind, which is why they must be protected against water infiltration, ice dams and premature wear of the roofing material.

In Canada, asphalt shingles and metal roofs are used predominantly in the residential sector. Asphalt shingles are the most common as they are cost-effective and easy to install. However, their lifespan is shorter compared to other types of roofing materials, such as metal and elastomeric membranes.

For years, the use of felt paper (black paper or 15 lb paper) under the roofing material was widespread given its water-repellent bituminous composition. Not only was this solution good practice at the time, but it was also one of the only affordable ones on the market.

Over time, waterproofing membranes have become more efficient and more durable. Technologies evolve, sometimes faster than the standards by which they are tested. Synthetic base sheet membranes are a good example of this.

FELT PAPER VS. SYNTHETIC ROOFING UNDERLAYMENTS

The differences between synthetic roofing underlayments and felt paper are quite numerous, although the way we use them is the same. The benefits of synthetic protectors range from the composition of the material to better durability, increased waterproofing and greater resistance to UV rays. All these have pushed the industry to review its practices and turn to this type of more efficient product to improve the waterproofing of roofs.

Unfortunately, as there were no specific standards to assess their quality, synthetic roofing underlayments were tested according to felt paper standards. This greatly limited the ability to effectively differentiate products and highlight their benefits.

NEW ASTM D8257 STANDARD

To rectify this, the American Society for Testing and Materials (ASTM) has just created the new D8257 Standard. This standard specifies the requirements for mechanically fastened polymer base sheet membranes for sloped roofs. It allows for better assessment of synthetic roofing underlayments and is much less restrictive than previous standards.

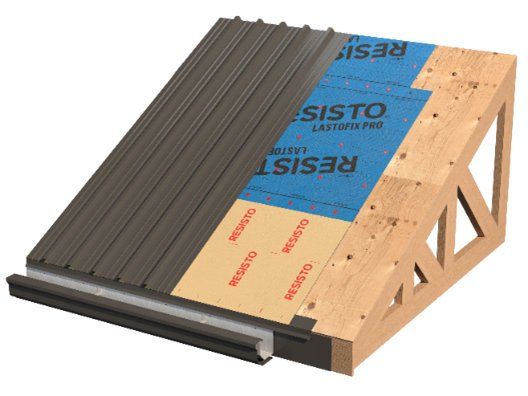

LASTOFIX AND LASTOFIX PRO: STRONGER AND MORE DURABLE

In order to meet the increased requirements of the new ASTM standard, RESISTO offers two new stronger and more durable synthetic roofing underlayments, LASTOFIX and LASTOFIX PRO. These products not only meet, but exceed the requirements of the standard, and do so at competitive prices, which allows you to avoid compromises when it comes to the waterproofing of your roof.

Additionally, these products provide superior protection against water infiltration. LASTOFIX PRO provides a superior anti-slip surface, better tensile and tear resistance as well as increased resistance to UV rays compared to the basic LASTOFIX version.

WHY USE OUR SYNTHETIC ROOFING UNDERLAYMENTS

Our products offer many benefits:

- Much lighter and stronger than felt paper

- Compatible with asphalt shingle and sheet metal roofing materials

- Protect the roof substrate before the roofing material is installed

- Create an additional barrier against weather and ice dams

- Quick and easy to install at any temperature

- Create an anti-slip surface allowing safe circulation

- 100% recyclable

- Covered by excellent warranties, among the best in the industry

These products can also be used with ICE & WATER PROTECTOR – LB1236 under asphalt shingles or ROOF UNDERLAYMENT – HIGH TEMPERATURE LASTOBOND PRO HT-N under sheet metal to protect eaves.